Dynamic landscape of modern Industrial Workbenches

Workstations in Modern Manufacturing stand as indispensable pillars of efficiency, organization, and productivity. These dedicated spaces within production facilities play a vital role in orchestrating the intricate dance of machinery, materials, and manpower that underpins the manufacturing process. From assembly lines to quality control stations, workstations serve as the beating heart of production, driving innovation, and ensuring operational excellence.

Workstations in Modern Manufacturing Efficiency Through Organization:

At the core of every well-designed workstation lies the principle of efficiency. By providing a designated area for specific tasks or operations, workstations minimize unnecessary movement and streamline workflow. Whether it’s assembling components, inspecting finished products, or packaging goods for shipment, having a dedicated workstation ensures that each task is carried out with precision and purpose, optimizing productivity and minimizing waste.

Ergonomics for Worker Well-being:

In an era where the well-being of the workforce is paramount, ergonomic design principles take center stage in workstation development. Ergonomically designed workstations are tailored to the needs of the workers, promoting good posture, reducing strain on muscles and joints, and minimizing the risk of repetitive stress injuries. By prioritizing worker comfort and safety, manufacturers not only enhance employee satisfaction but also improve overall productivity and morale.

Flexibility to Adapt and Innovate:

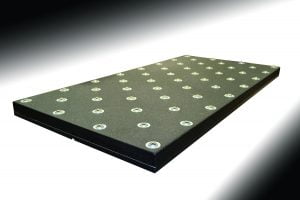

The manufacturing landscape is constantly evolving, driven by changing market demands, technological advancements, and shifting consumer preferences. Workstations play a crucial role in enabling flexibility and adaptability within manufacturing facilities. Modular workstations can be easily reconfigured or expanded to accommodate changes in production requirements, allowing manufacturers to respond quickly to new opportunities or challenges without disrupting operations.

Quality Control and Assurance:

Maintaining high standards of quality is non-negotiable in manufacturing. Workstations serve as key checkpoints in the quality control process, enabling manufacturers to monitor product quality at various stages of production. By incorporating inspection stations, testing equipment, and quality assurance protocols into workstations, manufacturers can identify defects or inconsistencies early in the process, ensuring that only products meeting stringent quality criteria reach the hands of customers.

Standardization for Consistency:

Consistency is the hallmark of successful manufacturing operations, and workstations play a pivotal role in achieving this goal. Standardized workstations follow best practices and standardized procedures, ensuring uniformity and consistency in operations across different production lines or shifts. Standardization simplifies training, reduces variability, and enhances overall process control, leading to improved product quality and customer satisfaction.

Documentation and Data Analysis:

In an era of data-driven decision-making, Omtec Corp Workstations at AT Auto Conveyor serve as data collection points within the manufacturing process. By capturing production data, tracking inventory levels, and documenting process parameters at each workstation, manufacturers gain valuable insights into performance metrics, production trends, and areas for improvement. This data-driven approach enables manufacturers to optimize processes, reduce costs, and drive continuous improvement throughout the organization.

In conclusion,

workstations are the backbone of modern manufacturing, providing the foundation upon which efficiency, quality, and innovation thrive. From promoting ergonomic well-being to facilitating flexibility and adaptability, workstations embody the principles of operational excellence that drive success in today’s competitive manufacturing landscape. As manufacturing continues to evolve, the importance of well-designed workstations in achieving operational excellence will only continue to grow.