The Challenge of Gondola Shelving

Gondola shelving is the backbone of retail stores across the world. From grocery aisles to hardware displays, gondola fixtures are designed to be durable, sturdy, and capable of holding thousands of pounds of merchandise. That’s great for day-to-day operations — but when it comes time to remodel, reset, or clean under them, moving gondola shelving quickly becomes a nightmare.

Traditionally, the process of moving gondolas involved:

- Unloading merchandise piece by piece.

- Dismantling shelving sections before relocating.

- Using a large crew of employees or contractors to muscle fixtures across the floor.

Not only is this time-consuming and expensive, but it also increases the risk of:

- Damaged merchandise during unloading and reloading.

- Lost sales due to store downtime.

- Employee injuries from heavy lifting.

The good news? There are modern solutions that allow retailers and contractors to move gondola shelving fully loaded, in a way that is safe, cost-effective, and efficient.

Why Safety Matters When Moving Gondola Shelving

Safety is the number one priority when relocating gondolas. These shelving units are heavy, often weighing hundreds of pounds per section, plus the weight of fully stocked merchandise. Improper methods can lead to:

- Tipped shelving and falling merchandise.

- Back injuries or muscle strains for workers.

- Floor damage that requires costly repair.

Using the right equipment ensures that shelving remains stable during movement. Products like FOURMI Gondola Skates and Hudson Haulers are designed specifically for this purpose. Unlike makeshift methods such as dollies or pallet jacks, these systems keep gondolas balanced, secure, and close to the floor — reducing the risk of tipping or sliding.

The Cost Factor: Why Old Methods Are Expensive

At first glance, it might seem “cheaper” to have staff unload and manually push gondolas. But in reality, the costs add up fast:

- Labor Costs: What takes 10 employees hours to complete can be done by 3 people with the right equipment in minutes.

- Merchandise Loss: Tags, dividers, and fragile items often get damaged during resets.

- Sales Loss: If an aisle is down for half a day, that’s revenue lost to competitors.

- Injury Costs: Worker’s comp claims from back injuries or accidents can cost far more than equipment ever would.

Modern gondola moving systems are an investment that pays for itself — often within the first use.

The Efficiency Advantage

Efficiency isn’t just about speed. It’s about making every move count with the least disruption to operations. Using skates and hauler systems, you can:

- Move shelving rows without unloading merchandise.

- Reconfigure store layouts overnight instead of over several days.

- Allow contractors (flooring, electricians, painters) to complete work faster.

- Clean under shelving thoroughly without dismantling.

The result is a cleaner, safer store that looks refreshed with minimal effort.

The Best Solutions for Moving Gondola Shelving

1. FOURMI Gondola Skates

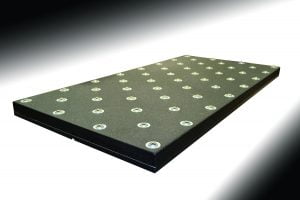

FOURMI is one of the most trusted names in gondola moving systems worldwide. Their skates are engineered from marine-grade aluminum and feature a unique three-bearing design that allows for unlimited 360° maneuverability.

Why FOURMI Works:

- Load Capacity: Each skate supports up to 1,800 lbs.

- Stability: Gondolas remain just 0.83” above the floor, ensuring perfect balance.

- Certified Safe: Approved by APAVE & SGS standards after years of testing.

- Durability: With minimal maintenance, FOURMI skates can last decades.

Kits Available:

- Case of 6 – Move up to 8 ft (2 sections). Perfect for small stores.

- Case of 12 – Move up to 20 ft (5 sections). The standard choice for most contractors.

- Case of 18 – Move up to 32 ft (8 sections). Ideal for large-scale remodels.

2. Hudson Haulers

For contractors in the U.S., the Hudson Hauler has become a popular solution, especially in the automotive industry for moving tire machines. But these compact, heavy-duty movers also work for smaller gondola sections and retail displays.

Advantages of Hudson Haulers:

- Affordable and easy to transport.

- Support up to 2,400 lbs per hauler.

- Compact design for tight spaces.

Best Use Cases:

- Smaller stores or shops.

- Moving individual machines (tire changers, cabinets, heavy tools).

- Complementary to larger skate systems.

📌 Shop Hudson Hauler Kits here

3. Toe Jacks & Lift Bars

Before you can position skates under gondola feet, you need a safe way to lift the fixture. That’s where toe jacks and lift bars come in.

- Toe Jacks: Heavy-duty hydraulic jacks capable of lifting several tons, making it easy to raise shelving just enough to slide skates underneath.

- Lift Bars: Provide leverage to raise gondolas by hand with minimal effort.

When bundled with skates, these tools create a complete gondola moving kit that maximizes safety and convenience.

📌 Shop Toe Jack Bundles here

Step-by-Step: How to Move Gondola Shelving the Right Way

- Prepare the Area

- Clear walkways and ensure the path is smooth.

- Communicate the plan with your team.

- Lift the Gondola Safely

- Use a toe jack or lift bar to raise shelving feet about 1 inch.

- Position the Skates

- Slide FOURMI skates or Hudson Haulers under the gondola feet.

- Ensure each is seated properly for balance.

- Move the Gondola

- Push the gondola slowly and evenly.

- Thanks to 360° bearings, you can move forward, backward, or sideways with ease.

- Reposition and Reset

- Once in place, remove skates and lower the gondola gently back onto the floor.

- Repeat the process as needed.

Real-World Applications

- Retail Resets: Move entire aisles overnight for new product layouts.

- Seasonal Promotions: Quickly reconfigure displays for holidays like Halloween and Christmas.

- Contractor Projects: Flooring, electrical, and remodeling crews save hours by moving loaded shelves.

- Cleaning: Sanitize under shelving without emptying it.

- Fixture Replacement: Swap old gondolas with new ones in record time.

Long-Term ROI of Gondola Moving Systems

The true value of investing in gondola moving systems comes down to:

- Time Savings: Projects that once took days now take hours.

- Labor Efficiency: Fewer employees required, lowering payroll costs.

- Merchandise Protection: Less damage = less shrink.

- Safety & Liability: Fewer injuries = fewer claims.

- Sales Retention: Remodel without closing aisles or losing customers.

Over time, the cost of equipment pays for itself many times over.

Conclusion: The Smarter Way to Move Gondola Shelving

Moving gondola shelving no longer has to be a dreaded, expensive process. With the right equipment — FOURMI skates, Hudson Haulers, and toe jacks — retailers and contractors can move fully loaded shelving safely, cost-effectively, and efficiently.

Whether you’re running a small shop or managing a full retail remodel, investing in gondola moving systems ensures your projects are faster, safer, and more profitable.

📌 Ready to simplify your next gondola move?