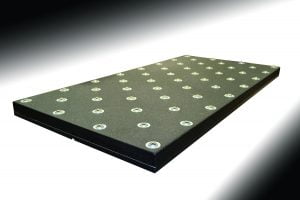

New Omtec Product

In the fast-paced world of manufacturing, efficiency and precision are paramount. Assembly lines, the heart of many production processes, require smooth, reliable movement of components and products. This is where Spring-Loaded Ball Transfer Units (BTUs) come into play, with the spring-loaded variant offering particular advantages. This blog post delves into the specifics of spring-loaded BTUs, their benefits, and why they are essential for modern assembly lines. We will also highlight top manufacturers, including Omtec Corp, a high competitor in this field.

What are Spring-Loaded Ball Transfer Units?

Ball Transfer Units (BTUs) are mechanical components that enable smooth and multi-directional movement of objects on assembly lines and material handling systems. They consist of a large load-bearing ball supported by smaller ball bearings, allowing for 360-degree movement.

Types of BTUs

There are various types of BTUs, including:

- Standard BTUs: Fixed position units for general use.

- Flange Mounted BTUs: Designed for bolting to surfaces.

- Spring-Loaded BTUs: Feature a spring mechanism for added flexibility and shock absorption.

Design and Components

Spring-loaded BTUs are engineered with a spring mechanism that allows the main ball to retract into the housing under load. This self-adjusting feature enables the BTU to handle varying loads and heights efficiently. The main components include:

- Load-bearing Ball: Typically made from hardened steel or stainless steel.

- Support Balls: Smaller balls that facilitate smooth movement.

- Spring Mechanism: Absorbs shocks and adjusts to load changes.

- Housing: Encases the components and provides structural support.

Materials Used

Spring-loaded BTUs are usually constructed from durable materials to withstand harsh environments and heavy loads. Common materials include:

- Stainless Steel: For corrosion resistance and strength.

- Carbon Steel: For high-load applications.

- Plastic: For lighter loads and specific environments.

Benefits of Spring-Loaded Ball Transfers in Assembly Lines

The primary advantage of spring-loaded BTUs is their self-adjusting capability. The spring mechanism allows the ball to retract under pressure, adapting to different load weights and heights. This ensures consistent contact and smooth movement, even on uneven surfaces.

Enhanced Smoothness and Control

Spring-loaded BTUs provide superior control and smoothness in moving components. This is particularly beneficial in assembly lines where precision is crucial. The consistent movement helps in maintaining alignment and reducing the risk of damage to delicate parts.

Shock Absorption

The spring mechanism acts as a shock absorber, reducing the impact of sudden loads and movements. This protects both the load and the BTU, extending the lifespan of the unit and minimizing maintenance needs.

Versatility in Applications

Spring-loaded BTUs are versatile and can be used in various settings within assembly lines. From transferring heavy automotive parts to handling delicate electronics, these units offer flexibility and reliability.

Applications in Assembly Lines

Automotive Industry

In the automotive industry, precision and efficiency are critical. Spring-loaded BTUs facilitate the smooth transfer of heavy components, such as engines and transmissions, across assembly lines. Their shock-absorbing properties protect sensitive parts from damage.

Electronics Manufacturing

In electronics manufacturing, delicate components require careful handling. Spring-loaded BTUs provide the necessary control and smooth movement, reducing the risk of static build-up and physical damage.

Packaging Lines

In packaging lines, spring-loaded BTUs enable the efficient movement of products, ensuring quick and accurate packaging. Their ability to handle varying loads makes them ideal for mixed product lines.

Inspection Stations

Inspection stations benefit from the precise control offered by spring-loaded BTUs. Products can be easily maneuvered for thorough inspection without risk of damage.

Installation and Maintenance of Spring-Loaded Ball Transfer

Installation Process

Installing spring-loaded BTUs involves several steps:

- Determine Load Requirements: Assess the load capacity needed for your specific application.

- Select Appropriate BTUs: Choose the right BTUs based on load capacity and environmental conditions.

- Prepare Mounting Surface: Ensure the surface is clean and level for proper installation.

- Install BTUs: Secure the units in place using bolts or other fasteners as required.

- Test for Smooth Movement: Ensure the BTUs provide the desired movement and make adjustments if necessary.

Maintenance Tips

Regular maintenance ensures the longevity and performance of spring-loaded BTUs:

- Routine Inspections: Check for wear and tear regularly.

- Lubrication: Apply appropriate lubricants to reduce friction and wear.

- Cleaning: Keep the units clean to prevent debris from affecting performance.

- Replacement of Worn Parts: Replace any worn or damaged components promptly to maintain efficiency.

Choosing the Right Spring-Loaded BTUs

Load Capacity

Selecting the right load capacity is crucial. Overloading BTUs can lead to premature failure, while underloading can result in inefficiency. Assess the maximum load the BTUs will need to handle and choose accordingly.

Environmental Conditions

Consider the operating environment when choosing materials. For corrosive environments, stainless steel is ideal. In clean room settings, plastic or specially coated BTUs may be necessary.

Compatibility with Existing Systems

Ensure the spring-loaded BTUs are compatible with your existing material handling systems. This includes checking dimensions, load capacity, and mounting requirements.

Top Manufacturers of Spring-Loaded Ball Transfer Units

Several manufacturers are known for producing high-quality spring-loaded BTUs. Here are some of the best:

Omtec Corp is a leading manufacturer of material handling components, including spring-loaded BTUs. Their products are known for their durability, precision, and innovative designs. Omtec’s spring-loaded BTUs are widely used in various industries due to their high performance and reliability. They can be purchased at AT Auto Conveyor

Other Leading Manufacturers

- SKF: Known for their extensive range of BTUs, including spring-loaded variants.

- Hudson Bearings: Offers a variety of BTUs designed for different industrial applications.

- Alwayse Engineering: A pioneer in the BTU market, providing high-quality spring-loaded units.

Case Studies

Automotive Assembly Line Efficiency

A major automotive manufacturer implemented Omtec Corp’s spring-loaded BTUs in their assembly line. The result was a 15% increase in efficiency, with smoother transitions and reduced downtime due to the shock-absorbing properties of the units.

Electronics Manufacturing Precision

An electronics company integrated spring-loaded BTUs into their inspection stations. This allowed for precise and damage-free handling of delicate components, leading to a significant reduction in product defects.

Future Trends and Innovations

Technological Advances

The future of BTUs lies in technological advancements. Innovations such as smart BTUs with sensors for real-time monitoring and feedback are on the horizon. These units will offer even greater control and efficiency in material handling.

Sustainability

Sustainability is becoming a key focus in manufacturing. Spring-loaded BTUs made from recyclable materials and designed for energy efficiency will play a crucial role in creating greener assembly lines.

Conclusion for Spring-Loaded Ball Transfer

Spring-loaded Ball Transfer Units are a critical component in modern assembly lines, offering numerous benefits such as self-adjusting capability, enhanced smoothness, shock absorption, and versatility. Their application spans various industries, from automotive to electronics, highlighting their importance in improving efficiency and precision.

Manufacturers like Omtec Corp continue to lead the way with high-quality, innovative BTUs that meet the demanding needs of today’s manufacturing processes. As technology advances and sustainability becomes a priority, the future of spring-loaded BTUs looks promising, ensuring they remain a vital part of material handling systems for years to come.

By understanding and implementing spring-loaded BTUs, assembly lines can achieve greater efficiency, reduced downtime, and improved product quality, ultimately leading to a more streamlined and effective production process.