Your cart is currently empty!

Omtec Pop Up ESD Ground Unit

$45.95

Product successfully added to the Quote List

Please fill in the fields below with the shipping destination details in order to calculate the shipping cost.

Free shipping on orders over $75

- No-Risk Money Back Guarantee!

- No Hassle Refunds

- Secure Payments

Description

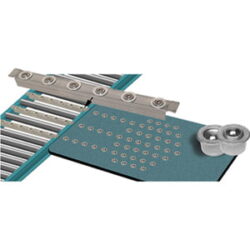

Omtec PUG: A Simple and Effective Solution for ESD Applications

Omtec’s patented PUG (Pop-Up Ground Unit) provides an easy and efficient solution for a wide range of ESD (Electrostatic Discharge) applications. Designed to integrate seamlessly into work surfaces not originally intended for ESD protection, the PUG ensures reliable grounding for sensitive materials and components.

Innovative Design for Continuous Grounding

The Omtec PUG features a spring-loaded brass pin on its top surface, maintaining consistent contact with your product to ensure effective grounding at all times.

- Retracted Position: The brass pin remains in contact with the product even when the unit is retracted, providing continuous ESD protection.

- Raised Position: When the unit is raised, the brass pin retracts slightly under minimal pressure while still grounding the product effectively.

The bottom of the PUG includes a threaded stud, allowing easy grounding to the work surface. This innovative design makes Omtec PUGs a reliable choice for ESD-sensitive environments.

Versatile and Easy Operation

Omtec PUGs can be operated using virtually any air control device:

- Non-Electric Options: Simple foot and hand valves without electrical components are commonly used.

- Electric Options: Sensing devices with electric solenoid valves offer automated operation.

Omtec provides a variety of kits to suit different operational needs:

- FRL Kits: Ensure the compressed air is Filtered, Regulated, and Lubricated.

- Non-Detent Foot Valve Kits and Detent Toggle Hand Valve Kits: Provide flexibility for manual operation.

For optimal performance, the regulator should be set at 50 PSI (3.447 bar). Omtec PUGs consume very low air volume, with each up-and-down cycle using just 0.00038 cubic feet (0.0000108 cubic meters) of air.

Seamless Integration and Installation

Omtec offers carbide-tipped bits for drilling and recessing holes in plastic, wood composite, and metal surfaces.

- Surface Thickness Requirements: Minimum thickness of 0.092 inches (2.34mm) for steel and 0.125 inches (3.18mm) for aluminum.

- Recessing Options: For flanged installations, rabbeting bits are also available.

Compatibility with Other Omtec Products

Omtec PUGs work seamlessly with other ergonomic transfer components, including:

- PPD Positioner Pads

- FBT Ball Transfers

- Insert Wheels and Rollers

- PBT Pop-Up Balls

Omtec PUGs: Efficient, Reliable, and Essential

Whether for assembly lines or sensitive workstations, Omtec PUGs provide unmatched reliability and versatility in grounding solutions. Pair them with other Omtec products to create a fully ergonomic and ESD-safe workspace. Contact us today to learn more!

Contact us now!

Related products

Product successfully added to the Quote List

Product successfully added to the Quote List

Product successfully added to the Quote List

Product successfully added to the Quote List