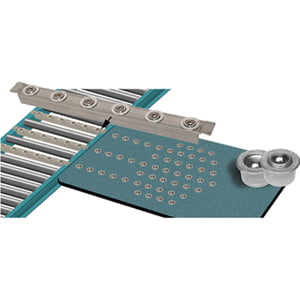

Pop Up Ball Transfer for Integrate Workbench and Conveyor

Integrating Omtec PBT Workbench Tops with Roller Conveyors Using Omtec Pop Up Ball Transfer Strips and Ball Transfers

Enhance Your Workflow with Omtec Pop-Up Ball Transfers

Efficiently integrate your workbench tops with roller conveyors using Omtec PBT Ball Transfer Strips and Omtec PBT Ball Transfers. With a simple flip of a switch, these innovative components streamline material handling, improving productivity and organization in progressive assembly line layouts.

Seamless Transition Between Conveyor and Workbench

- At the Flip of a Switch:

- Omtec Pop-Up Ball Transfers raise above the conveyor rollers and work surface, allowing items to be effortlessly moved off the conveyor and onto the workbench.

- Flip the Switch Again:

- The ball transfers retract, firmly stabilizing the item on the workbench. This stable positioning allows operators to perform tasks without the item shifting or moving, ensuring accuracy and safety.

Organized Assembly Lines = Increased Production

The use of Omtec Ball Transfer Tables facilitates more organized and efficient assembly lines. Below are two common progressive assembly line layouts showcasing the advantages of integrating Omtec components.

- Single Conveyor Flow:

- Items proceed along the conveyor to designated workstations.

- Operators perform required assembly tasks at each station.

- Completed items advance to the inspection and shipping areas.

- Dual Conveyor Flow:

- Items move along the main conveyor for assembly.

- After assembly, a secondary conveyor returns the item to the line supervisor for final inspection before shipping.

These layouts demonstrate the flexibility of progressive assembly lines. Conveyor lengths between stations can be adjusted to allow for online storage during production surges. Tasks that take longer can be split between multiple stations to reduce delays, and unused stations can remain unattended to optimize resource allocation.

How Omtec Pop-Up Ball Transfers Improve Workflow

- Smooth Transition:

- Items travel along the conveyor to a position over the Omtec Pop-Up Ball Transfer Strips. When retracted, the ball transfers allow free movement along the rollers without interference.

- Effortless Transfer:

- Operators activate the ball transfers, raising them to move items with minimal effort from the conveyor to the workbench.

- Stable Positioning:

- Once the item is on the workbench, the ball transfers are retracted, stabilizing the item securely for precise and efficient task execution.

Streamline Your Assembly Line

Integrating Omtec PBT Workbench Tops with Roller Conveyors using Pop-Up Ball Transfers ensures smooth transitions, stable work surfaces, and flexible production layouts. Optimize your assembly line today with Omtec’s innovative solutions!

Contact us for a Quote