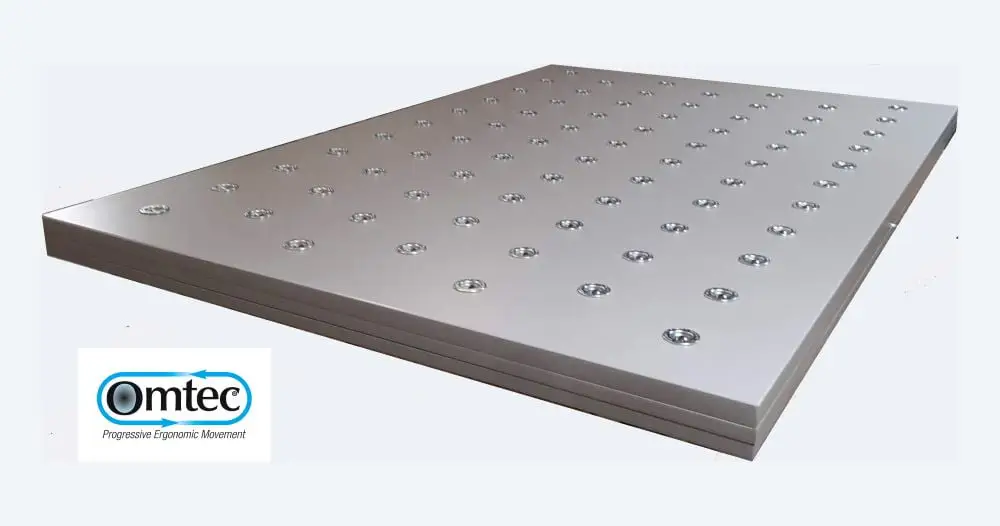

Ball Transfer Tables

Ball Transfer Tables are essential tools for efficient material handling, offering smooth, multi-directional movement for heavy loads with minimal effort. Designed to streamline workflows in manufacturing, assembly, and packaging environments, these tables improve productivity and reduce strain during operations. Whether you’re transferring products between workstations or reorienting items on a production line, tables provide reliable performance and versatility. Explore a range of sizes and configurations to meet the demands of your industrial applications.

Features and Benefits of Ball Transfer Tables: Roller Ball Conveyor Table Tops

Easy Integration: Our Ball Tables can be easily integrated into existing conveyor systems or used as standalone units, enhancing the efficiency of your operations without the need for extensive modifications.

View Omtec’s Application Guide application-booklet.pdf (omtec.com)

Versatility: Our Ball Transfer Tables are suitable for a wide range of applications, including loading and unloading of trucks, assembly lines, conveyor systems, and more.

Smooth Movement: The precisely engineered ball transfers ensure smooth and frictionless movement, reducing the effort required to transfer heavy loads.

360-Degree Rotation: With the ability to rotate in any direction, our Ball Transfer Tables provide unmatched flexibility, allowing operators to maneuver materials with ease.

Durable Construction: Crafted from high-quality materials, our tables are built to withstand heavy loads and rugged industrial environments, ensuring long-lasting performance and reliability.

Customization Options: We offer customizable solutions to meet your specific requirements, including different sizes, configurations, and load capacities.

Applications for Ball Conveyors

Packaging: Improve packaging efficiency by eliminating friction and resistance during material handling.

Material Handling: Transfer heavy or awkwardly shaped items with ease.

Assembly Lines: Facilitate the assembly process by allowing for smooth movement of components.

Shipping and Receiving: Expedite loading and unloading processes for trucks and containers.

Custom Ball Work Tops

With our commitment to quality, reliability, and customer satisfaction, At Auto Conveyor is your trusted partner for innovative material handling solutions. Explore our range of Ball Transfer Tables and experience the difference they can make in optimizing your workflow and increasing operational efficiency.

For inquiries, customization options, or to request a quote at the bottom of the page!

AT Auto Conveyor does prepare quotes for Omtec Inline Ball Transfer Tables. Tables can come in different sizes, wood, metal, color, and edge banding. We also can incorporate Pneumatic Pop Up Ball Transfers, Fixed Ball Transfers, Skate Wheels, Rollers, Pug’s, and Pneumatic Pop Up Pad Stops. We can also make aluminum frames for the table to sit on…

Why Choose Us

When it comes to ball transfer tables, we stand out as the trusted choice for quality, customization, and reliability. Here’s why:

- Superior Quality: Our ball transfer tables are crafted with precision and high-grade materials to ensure durability and long-lasting performance.

- Custom Solutions: We offer a variety of sizes, configurations, and load capacities to meet your specific application needs.

- Competitive Pricing: Enjoy premium products at competitive prices, ensuring excellent value for your investment.

- Expert Support: Our knowledgeable team is here to guide you, from selecting the right table to after-sales support.

- Fast Delivery: We understand your time is valuable, so we prioritize quick turnaround and delivery.

Choose us for ball transfer tables that deliver efficiency, reliability, and top-notch customer service tailored to your requirements.

View the Installers Guide installation-guide.pdf (omtec.com)

View the Application Worksheet

1 p22-prompt-strip-and-surfaces.pdf (omtec.com)

2p23-prompt-item-information.pdf (omtec.com)

Submit a Quote request bellow! or call 508 360 1611 and we will get back to you as soon as we can. We are open Monday -Friday 7 Am – 5Pm but try to answer and messages one weekends or at night.

The Need for Ball Tables in Material Handling

Ball Transfer Tables play a crucial role in modern material handling systems, offering efficient solutions for moving and positioning items in industrial, commercial, and logistical environments. Their unique design and versatility make them indispensable for a variety of applications where precision, ease of movement, and operational efficiency are essential.

Key Reasons for the Need for Ball Transfer Tables

- Efficient Material Movement:

- Ball Transfer Tables enable smooth, multidirectional movement of items, reducing the effort required to transfer, rotate, or position heavy or bulky loads.

- Ideal for optimizing workflows in conveyor systems, assembly lines, and packaging stations.

- Reduced Manual Labor:

- By minimizing the need for lifting, dragging, or repositioning items, these tables help reduce physical strain on workers.

- Improves workplace ergonomics and reduces the risk of injuries, leading to a safer and more comfortable working environment.

- Precision and Control:

- The multidirectional movement offered by ball transfers ensures precise positioning of materials during assembly, inspection, or packaging processes.

- Particularly useful in applications where accuracy is critical, such as electronics assembly or quality control.

- Versatility Across Industries:

- Ball Transfer Tables are suitable for a wide range of industries, including manufacturing, warehousing, automotive, aerospace, and food processing.

- They can handle various load types, from lightweight components to heavy-duty pallets.

- Time and Cost Efficiency:

- By streamlining the movement and positioning of materials, these tables reduce operational downtime and increase productivity.

- Lower labor costs by reducing the need for multiple workers to handle a single task.

- Customizable Solutions:

- Available in various sizes, configurations, and materials, including stainless steel for hygienic environments or nylon for non-marking applications.

- Easily integrated into existing material handling systems for tailored solutions.