How Positioner Pads help in a conveyor system can offer several benefits to a business in manufacturing. Here are some ways it can help:

How Positioner Pads help Precision and Control:

How Positioner Pads help provide precise control over the positioning of items on the conveyor. This is crucial in manufacturing processes where accurate alignment or spacing of products is required.

Pneumatic positioner pads provide precise control over the positioning of items on the conveyor. This is crucial in manufacturing processes where accurate alignment or spacing of products is required.

Automated Adjustments:

The pneumatic system allows for automated adjustments, reducing the need for manual labor. This can lead to increased efficiency and productivity as the positioning can be controlled automatically based on the manufacturing requirements.

The pneumatic system allows for automated adjustments, reducing the need for manual labor. This can lead to increased efficiency and productivity as the positioning can be controlled automatically based on the manufacturing requirements.

Increased Throughput:

With automated and precise positioning, the manufacturing process can achieve higher throughput. This is particularly beneficial in high-volume production environments where optimizing the conveyor system’s performance is essential.

With automated and precise positioning, the manufacturing process can achieve higher throughput. This is particularly beneficial in high-volume production environments where optimizing the conveyor system’s performance is essential.

Reduced Downtime:

Pneumatic systems are known for their reliability. Implementing a pneumatic positioner pad can contribute to reduced downtime as the automated system is less prone to errors and requires less maintenance compared to manual adjustments.

Pneumatic systems are known for their reliability. Implementing a pneumatic positioner pad can contribute to reduced downtime as the automated system is less prone to errors and requires less maintenance compared to manual adjustments.

Flexibility in Production:

Pneumatic positioner pads offer flexibility in production setups. They can be easily adjusted or programmed to accommodate different product sizes, shapes, or configurations, allowing for quick changes in the manufacturing line.

Pneumatic positioner pads offer flexibility in production setups. They can be easily adjusted or programmed to accommodate different product sizes, shapes, or configurations, allowing for quick changes in the manufacturing line.

Quality Control:

Precision positioning is crucial for maintaining product quality. Pneumatic positioner pads can ensure that products are correctly aligned during the manufacturing process, reducing defects and improving overall product quality.

Precision positioning is crucial for maintaining product quality. Pneumatic positioner pads can ensure that products are correctly aligned during the manufacturing process, reducing defects and improving overall product quality.

Enhanced Safety:

Automated positioning through pneumatic systems can contribute to a safer working environment by minimizing manual handling of products and reducing the risk of injuries associated with repetitive tasks.

Automated positioning through pneumatic systems can contribute to a safer working environment by minimizing manual handling of products and reducing the risk of injuries associated with repetitive tasks.

Energy Efficiency:

Pneumatic systems can be energy-efficient when designed and operated effectively. They can contribute to cost savings in the long run by optimizing energy usage in the manufacturing process.

Pneumatic systems can be energy-efficient when designed and operated effectively. They can contribute to cost savings in the long run by optimizing energy usage in the manufacturing process.

Integration with Other Systems:

Pneumatic positioner pads can be integrated into larger automation systems, providing seamless coordination with other manufacturing equipment. This integration contributes to a more streamlined and efficient production process.

Pneumatic positioner pads can be integrated into larger automation systems, providing seamless coordination with other manufacturing equipment. This integration contributes to a more streamlined and efficient production process.

Adaptability to Various Industries:

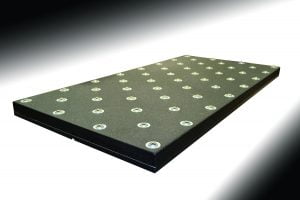

Omtec Corp PPD-1 Pneumatic Pop Up Positioner Pad (atautoconveyor.com) are versatile and can be applied in various industries, making them suitable for a wide range of manufacturing applications.

Omtec Corp PPD-1 Pneumatic Pop Up Positioner Pad (atautoconveyor.com) are versatile and can be applied in various industries, making them suitable for a wide range of manufacturing applications.

In summary, implementing a pneumatic positioner pad in a conveyor system can lead to improved efficiency, precision, and overall productivity in the manufacturing process. It provides a scalable and adaptable solution that can contribute to the success of a business in the manufacturing industry.