In manufacturing and material handling, every second counts. Workers often struggle with moving heavy loads across workstations. This slows production and increases the risk of injuries. There’s a better solution — ball transfer tables.

What Are Ball Transfer Tables?

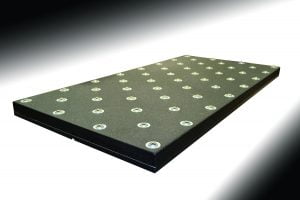

Ball transfer tables use multiple ball transfer units mounted into a flat surface. These units allow products to glide in any direction with minimal effort. Instead of pushing or lifting, a worker can move an item with one hand.

Benefits of Ball Transfer Tables

1. Increased Efficiency

Ball transfer tables make product transfers fast. Items can shift, rotate, and align without slowing production.

2. Improved Safety

Heavy lifting creates strain and injuries. Ball transfer tables reduce physical effort. Workers stay safe while productivity rises.

3. 360° Flexibility

Unlike roller conveyors that only move in one direction, ball transfers move products forward, sideways, or at an angle. This makes them perfect for assembly lines and workstations.

4. Customizable for Any Industry

Tables can be built in different sizes with various spacing between the ball transfers. Industries from automotive to logistics use them daily.

Common Applications

- Automotive: Moving transmissions, engines, or tires.

- Manufacturing: Handling sheet metal, panels, and assemblies.

- Logistics: Transferring boxes between conveyors.

- Packaging: Aligning and positioning products before sealing.

Why Choose AT Auto Conveyor?

AT Auto Conveyor offers durable ball transfer tables built to order. With access to multiple suppliers, we provide flexible options to meet your exact needs. Customers benefit from:

- Competitive pricing

- Fast quotes

- Reliable support

Conclusion

Ball transfer tables save time, cut labor, and improve workplace safety. Whether you run an auto shop, warehouse, or manufacturing line, adding them to your workflow delivers results.