Your cart is currently empty!

The Future of Aerospace Material Handling: Ball Transfer Units Leading the Way

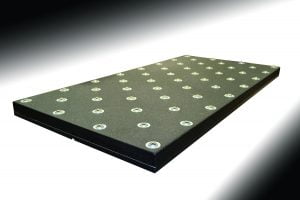

Ball Transfer Units

As we look ahead to the future of aerospace manufacturing, one thing is certain: innovation will continue to drive progress in every aspect of the industry. From advanced materials and cutting-edge technologies to streamlined processes and optimized workflows, aerospace manufacturers are constantly seeking new ways to improve efficiency, precision, and safety. Among the many innovations poised to shape the future of aerospace material handling, Ball Transfer Units (BTUs) stand out as a cornerstone of progress.

Unleashing the Potential of BTUs in Aerospace

Ball Transfer Units have long been recognized for their versatility and efficiency in material handling applications across various industries. In the aerospace sector, where precision and reliability are paramount, the potential of BTUs remains largely untapped. However, as technology continues to evolve and demand for higher efficiency grows, BTUs are poised to play an increasingly significant role in aerospace manufacturing processes of the future.

Advanced Materials and Lightweight Construction

One of the key trends shaping the future of aerospace manufacturing is the use of advanced materials and lightweight construction techniques. As aircraft designs become more complex and fuel efficiency becomes a greater priority, manufacturers are turning to materials such as carbon fiber composites and titanium alloys. BTUs, with their ability to handle heavy loads while minimizing weight and friction, are well-suited to support the handling of these advanced materials throughout the manufacturing process.

Automation and Robotics Integration

Automation and robotics are reshaping the aerospace industry, enabling greater precision, efficiency, and scalability in manufacturing operations. In the future, BTUs will play a vital role in facilitating the seamless integration of automated material handling systems, allowing robots to effortlessly move and position components with precision and accuracy. This integration will not only increase productivity but also enhance worker safety by reducing the need for manual handling of heavy or awkwardly shaped parts.

Enhanced Connectivity and Data Analytics

The rise of Industry 4.0 technologies is ushering in a new era of connectivity and data-driven decision-making in aerospace manufacturing. BTUs equipped with sensors and connectivity features will enable real-time monitoring of material handling processes, providing valuable insights into efficiency, performance, and maintenance needs. By leveraging data analytics, aerospace manufacturers can optimize their material handling workflows, identify areas for improvement, and proactively address issues before they arise.

Sustainable Manufacturing Practices

Sustainability is an increasingly important consideration in aerospace manufacturing, with companies striving to minimize environmental impact throughout the product lifecycle. BTUs, with their energy-efficient design and ability to reduce material waste through precise handling, align perfectly with the industry’s sustainability goals. In the future, we can expect to see BTUs playing a central role in sustainable manufacturing practices, helping aerospace companies minimize their carbon footprint while maintaining high standards of quality and efficiency.

Conclusion: Embracing the Future with BTUs

As aerospace manufacturing continues to evolve, Ball Transfer Units will remain at the forefront of innovation, driving efficiency, precision, and sustainability in material handling processes. By embracing the potential of BTUs and integrating them into advanced aerospace manufacturing systems of the future, companies can unlock new levels of productivity, reliability, and competitiveness. As we look ahead to the future of aerospace manufacturing, one thing is clear: with BTUs leading the way, the sky’s the limit.