Lean Palletizing Experience

From online validation and design to your end-of-line productivity.

1. Select

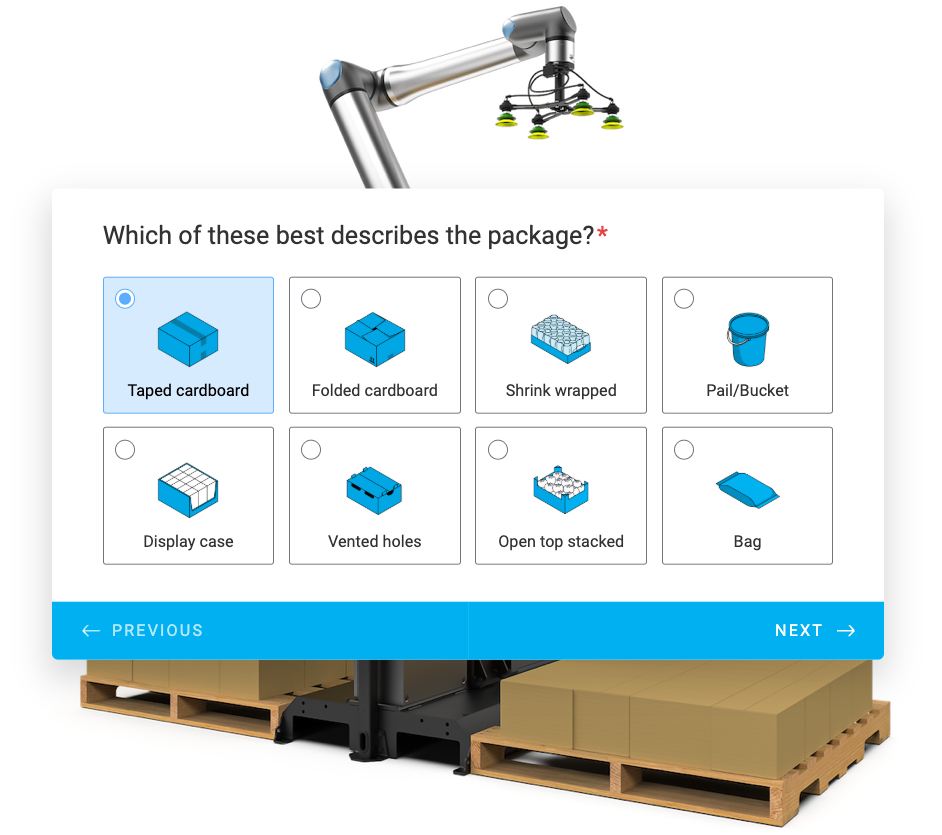

Select the right palletizing station and confirm feasibility with our Palletizing Fit Tool. In a matter of minutes, you’ll know which setup works best for you. You’ll also receive:

A 3D simulation tailored to your factory requirements

A detailed ROI, price range and payback period calculation

A comprehensive report you can share with your team

Test your setup in minutes

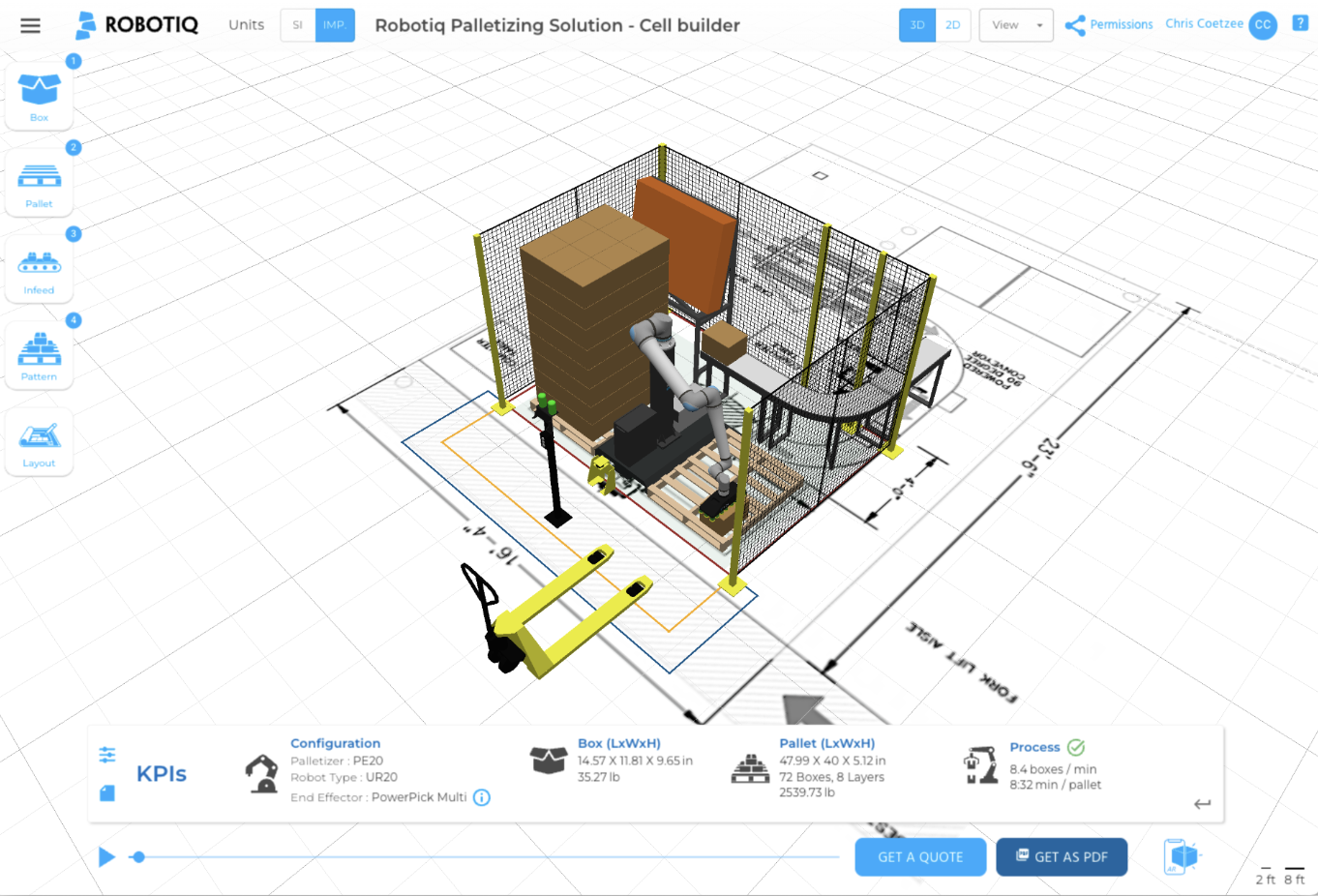

2. Simulate

Watch your palletizing cell come to life! Collaborate in our online Configurator to simulate real operations on your floor layout.

3. See

Our partner network is spread across the globe. There is bound to be one near you!

Get a hands-on look with your own products. See a PAL in action at your local Robotiq Expert Partner facility.

4. Start

Launch into production with easy-to-use PAL software, plus the support and training you need.

5. Scale

Expand PAL deployments to your other lines to accelerate ROI and boost productivity.

.jpg?width=1779&height=1000&name=Robotiq%20Background%20(Cascade%20Coffee).jpg)

What’s included in Lean Palletizing?

With Lean Palletizing, you get the palletizer that fits your operation best: PAL Ready or PAL Series.

Both options allow you to start fast, scale with confidence, and get:

- The same intuitive software and operator experience

- The same digital tools and deployment confidence

- The same Lean Robotics design principles

- The same global partner network and support

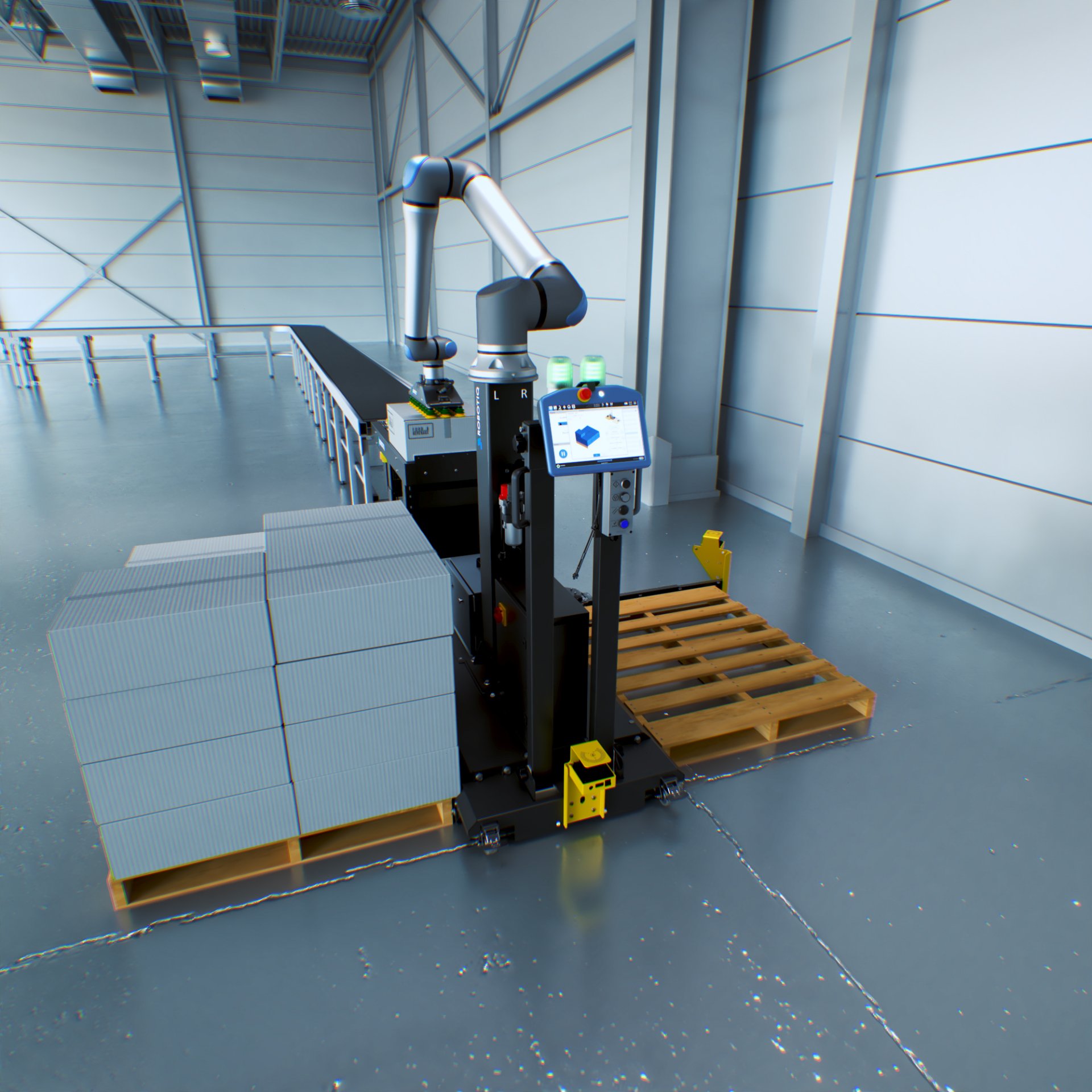

Production-ready palletizer

A fully assembled, robotic palletizing cell, designed for rapid installs.

Modular palletizers

A configurable palletizing option built from Robotiq standard models PE/AX Series and modules, supported by certified partners or Robotiq Installation Services.

PAL Ready

Get started fast and easy

Production-ready to skip project design and validation steps for faster deployment.

Fast and predictable ROI

Reduced delays, no production stop, no extra engineering required.

Confidence to grow

Scale ROI across lines and factories with one seamless operator experience, powered by PAL Ready and PAL Series.

PAL Ready

Smooth transition from your upstream conveyor, automatically delivering boxes at the right time and the right place.

Flexible gripper with no changeovers between products.

PAL Ready

Anchorless redeployment in under 10 minutes:

- Enable multiple production lines with low-volume production

- Support washdown zoning for food & bev

- Empower any team member – no tools, no forklifts or engineering support required.

PAL Ready

Work made easier and safer for your operators.

Robotiq puts the operator experience first:

Flexible and robust software – Easy to learn and intuitive to use, so operators get productive fast.

Safety package – Keeps the cell open and accessible, ensuring a safe workspace without bulky fences.

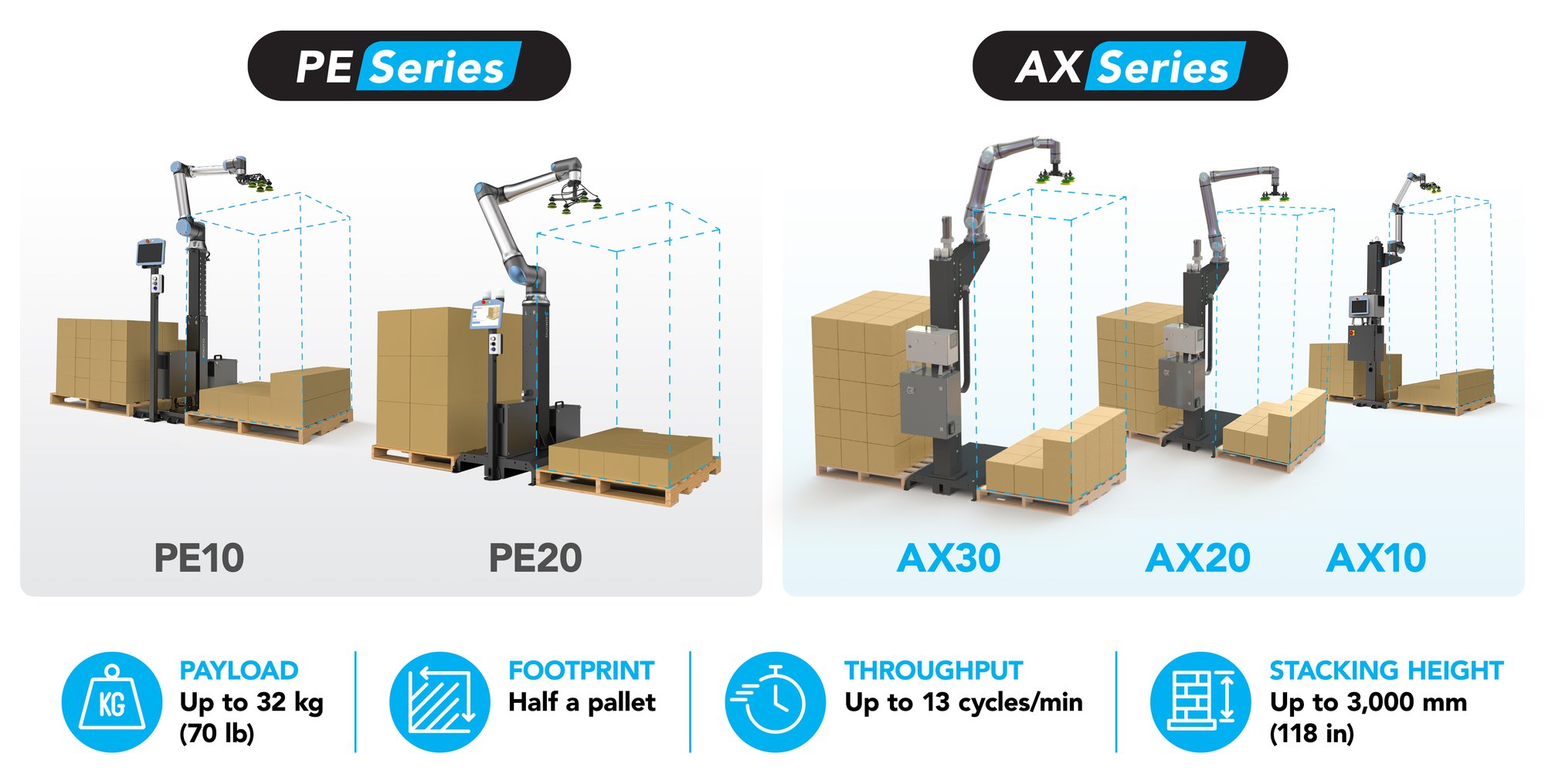

PE Series / AX Series

The PE Series is ideal for facilities with fewer pallet height variations. By mounting cobots on a pedestal, it maximizes floor space while delivering reliable performance in compact areas.

The AX Series uses a 7th axis as a linear transfer system to extend the robot’s vertical reach. It offers the fastest cycle times and the greatest reach of any comparable palletizing system — all within a compact footprint.

CoPilot palletizing software that works like your best operator

- Visual setup requires no code

- Auto-optimizes trajectories

- Handles obstacles and tight layouts

- Allows for cloning and reusing recipes

- Built-in Force & Torque sensor for stacking precision