Omtec PPD Positioner Pad Conveyor Workstation: Revolutionizing Assembly Line Productivity

In the fast-paced world of industrial production, efficiency and precision are critical. The Omtec PPD Positioner Pad Conveyor Workstation is designed to transform conveyor roller systems into ergonomic, productive, and flexible assembly or production lines. This innovative solution leverages PPD Positioner Pad Strips to secure and stabilize items during essential tasks, ensuring accuracy and workflow efficiency.

Ideal for Progressive Assembly Lines

The PPD Positioner Pad Strips are engineered for use in modular roller conveyor systems, making them perfect for creating flexible progressive assembly lines or straight production lines. Whether your operation involves assembling items that begin as a chassis or frame and evolve with added components as they progress, these strips provide the stability and control needed for precise task execution at every stage.

Seamless Integration with Conveyor Systems

Omtec PPD Positioner Pad Strips are designed to fit virtually all gravity roller and power roller conveyor systems. Their modular design ensures they can be seamlessly integrated into existing setups, allowing businesses to upgrade their conveyor lines without extensive modifications. This adaptability makes it easy to convert almost any roller conveyor into a highly efficient progressive assembly line.

Key Features and Functionality

- Stabilizing Items During Tasks

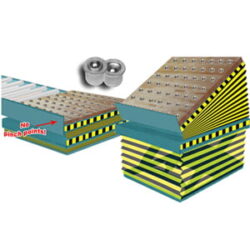

With the flick of a switch, the Omtec PPD Positioner Pads raise above the conveyor rollers to firmly locate items in a stable work position. This feature is particularly valuable for tasks requiring precision, such as component assembly, inspections, or detailed adjustments. - Uninterrupted Workflow

When a specific workstation is not needed for a production run, the PPD Positioner Pads can remain in their retracted position, allowing items to travel seamlessly along the conveyor to subsequent stations. This flexibility ensures the line remains efficient, even when certain tasks are bypassed. - Modular and Flexible Design

The modular nature of the PPD Positioner Pad Strips allows them to be customized for various conveyor configurations, making them suitable for a wide range of industries and applications. From packing and shipping lines to progressive assembly processes, these strips offer unparalleled adaptability. - Ergonomic Benefits

By securely holding items in place, the PPD Positioner Pads reduce the need for manual repositioning, minimizing worker strain and enhancing safety. This ergonomic design promotes a healthier work environment while boosting productivity.

How It Works

- Item Travel:

Items move along the conveyor rollers to a position directly over the Omtec patented PPD Positioner Pad Strips. - Positioning:

The operator activates the positioner pads, raising them above the rollers to firmly locate and stabilize the item. This ensures that the item remains securely in place while the required task is performed. - Completion and Continuation:

Once the task is completed, the pads can be lowered, allowing the item to move smoothly to the next station.

Enhanced Productivity with Omtec Ergonomic Transfers

Omtec’s PPD Positioner Pad Conveyor Workstation is not just about stability—it’s about creating flexible and efficient workflows. By incorporating Omtec Ergonomic Transfers, businesses can improve productivity across packing, shipping, and progressive assembly lines. Tasks are completed faster, with greater accuracy, and less physical effort, resulting in higher output and reduced operational costs.

Applications Across Industries

The versatility of the Omtec PPD Positioner Pad Conveyor Workstation makes it suitable for a wide range of industrial applications:

- Assembly Lines: Perfect for progressive assembly tasks, such as adding components to a chassis or frame as it moves along the conveyor.

- Inspection Stations: Provides a stable platform for quality checks and detailed inspections.

- Packing and Shipping Lines: Ensures items remain in place during packaging and labeling tasks.

- Production Lines: Streamlines operations by securely holding items for various production processes.

Why Choose Omtec PPD Positioner Pad Conveyor Workstations?

- Ease of Integration:

The modular design ensures easy installation into existing conveyor systems. - Flexibility:

Workstations can be used or bypassed as needed, offering unparalleled adaptability for varying production demands. - Enhanced Ergonomics:

Reduces manual handling, improving worker safety and comfort. - Productivity Boost:

Stabilizes items during tasks, ensuring precision and reducing rework. - Customizable Solutions:

Infinite configuration possibilities make it suitable for virtually any task-specific application.

Conclusion

The Omtec PPD Positioner Pad Conveyor Workstation is an innovative solution designed to meet the demands of modern production and assembly lines. By combining stability, flexibility, and ergonomic benefits, it enhances productivity while ensuring precision and worker safety. Whether you’re assembling complex products, conducting detailed inspections, or streamlining your packing and shipping processes, Omtec’s PPD Positioner Pad Strips provide the tools you need to succeed in today’s competitive industrial landscape. Upgrade your conveyor system with Omtec and experience the future of efficient production.

Get a quote! Contact US!