Versatile and Efficient Material Handling Solution

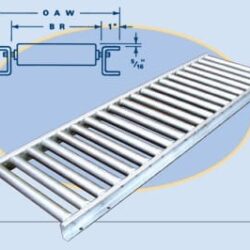

The Martin Gregory Gravity Roller Conveyor is a reliable and efficient solution for material handling across a wide range of industries. Designed to streamline workflows, enhance productivity, and reduce manual labor, this conveyor system offers a cost-effective way to transport goods with minimal effort. With roller sizes ranging from 1 3/8 inches to 3 1/2 inches, the Martin Gregory Gravity Roller Conveyor can be customized to meet the specific needs of your operation.

Key Features of the Martin Gregory Gravity Roller Conveyor

1. Durable Construction

The gravity roller conveyor is built to withstand demanding environments and heavy use. Each component is engineered for strength and durability, ensuring long-lasting performance in industrial, commercial, and warehouse settings.

2. Range of Roller Sizes

The conveyor offers roller sizes from 1 3/8 inches to 3 1/2 inches, allowing for optimal customization based on the size, weight, and nature of the materials being transported. Smaller rollers are ideal for lighter loads and tighter curves, while larger rollers handle heavier items with ease.

3. Gravity-Powered Operation

This conveyor relies on gravity to move materials, eliminating the need for motors or power sources. This design reduces energy costs, minimizes maintenance, and provides a quiet and efficient material handling solution.

4. Modular Design

The modular design of the Martin Gregory Gravity Roller Conveyor allows for seamless integration into existing systems or easy expansion of current setups. With a wide range of configurations available, the conveyor can adapt to straight, curved, or angled layouts, ensuring versatility in any space.

5. Low-Maintenance Solution

With minimal moving parts, the gravity roller conveyor requires little maintenance compared to powered systems. The simplicity of its design ensures consistent performance and reduces downtime, making it a dependable choice for high-demand operations.

6. Versatile Material Compatibility

The conveyor is suitable for handling various materials, including boxes, pallets, totes, and irregularly shaped items. Its robust rollers ensure smooth and reliable transport, even for heavier loads.

Applications of the Martin Gregory Gravity Roller Conveyor

The Martin Gregory Gravity Roller Conveyor is versatile and adaptable, making it suitable for a variety of industries and use cases:

1. Warehousing and Distribution

Streamline operations in warehouses and distribution centers by incorporating gravity roller conveyors to efficiently move goods from storage to shipping areas.

2. Manufacturing and Assembly Lines

Enhance productivity on manufacturing floors and assembly lines by using the conveyor to transport components and finished products between workstations.

3. Retail and E-Commerce Fulfillment

Optimize order fulfillment processes in retail and e-commerce facilities by enabling fast and accurate movement of goods through picking, packing, and shipping stages.

4. Packaging and Shipping

Simplify packaging and shipping workflows by using the conveyor to transport boxes, crates, and pallets to loading docks or packing stations.

5. Food and Beverage Industry

The gravity roller conveyor is an excellent choice for non-powered material handling in food and beverage facilities, ensuring safe and efficient transport of packaged goods.

Benefits of the Martin Gregory Gravity Roller Conveyor

1. Cost-Effective Solution

The gravity-powered design eliminates the need for motors and electrical components, reducing upfront costs and long-term energy expenses.

2. Customizable Options

With roller sizes ranging from 1 3/8 inches to 3 1/2 inches, the conveyor can be tailored to meet the unique needs of your operation, ensuring optimal performance.

3. Enhanced Efficiency

Gravity-powered movement simplifies the transport of goods, improving workflow efficiency and reducing manual labor requirements.

4. Durable and Long-Lasting

Constructed from high-quality materials, the conveyor is designed to withstand heavy use, ensuring reliable performance in demanding environments.

5. Easy Installation and Integration

The modular design makes installation straightforward and allows for seamless integration into existing conveyor systems or workflows.

6. Environmentally Friendly

By eliminating the need for electricity, the gravity roller conveyor offers an eco-friendly material handling solution.

7. Low Maintenance Requirements

The conveyor’s simple design and durable components reduce the need for frequent maintenance, ensuring consistent performance with minimal downtime.

Technical Specifications

| Feature | Details |

|---|---|

| Roller Sizes | 1 3/8″ to 3 1/2″ |

| Operation | Gravity-powered |

| Material Compatibility | Boxes, pallets, totes, irregularly shaped items |

| Applications | Warehousing, manufacturing, retail, shipping |

| Configurations | Straight, curved, angled |

How the Martin Gregory Gravity Roller Conveyor Works

- Gravity-Powered Movement The conveyor uses gravity to move items along its rollers, requiring no external power source. Items placed at a higher elevation naturally move downward, creating a smooth and efficient flow.

- Customizable Roller Sizes With roller sizes ranging from 1 3/8 inches to 3 1/2 inches, the conveyor can handle a wide range of materials, from lightweight packages to heavy pallets.

- Simple and Efficient Design The straightforward design ensures consistent operation with minimal maintenance, making it a dependable choice for high-volume applications.

Why Choose Martin Gregory Gravity Roller Conveyor?

1. Proven Reliability

Backed by a reputation for quality and performance, the Martin Gregory Gravity Roller Conveyor is trusted by businesses across industries for its dependable operation.

2. Versatile Design

With a wide range of roller sizes and configurations, the conveyor adapts to various materials and layouts, ensuring it meets your unique requirements.

3. Low Operational Costs

The gravity-powered system reduces energy consumption and maintenance expenses, making it a cost-effective choice for material handling.

4. Enhanced Productivity

By streamlining workflows and reducing manual labor, the conveyor improves efficiency and throughput in any operation.

5. Long-Term Durability

Constructed from high-quality materials, the conveyor is built to last, even in demanding industrial environments.

Conclusion

The Martin Gregory Gravity Roller Conveyor is a versatile, efficient, and cost-effective solution for material handling in industrial, commercial, and warehouse settings. With its range of roller sizes, durable construction, and gravity-powered operation, this conveyor provides a dependable way to streamline workflows and enhance productivity.

Invest in the Martin Gregory Gravity Roller Conveyor today to experience the perfect balance of performance, reliability, and efficiency for your material handling needs. Whether you’re upgrading an existing system or setting up a new workflow, this conveyor is designed to meet and exceed your expectations.

Contact us for a quote!